Clutch Replacement - 924/944/968, J Pasha, Excellence, Oct 1999, pg 143-149. This is a really good complete procedure with pictures for clutch replacement.

General Tips on Clutch Replacement

A collection of tips, some included in the above procedure, some not, taken from the collective knowledge of the discussion board, that you should be aware of or do while replacing the clutch. The stock (original) Sachs clutch kit (clutch disc, pressure plate, and throwout bearing) is very good, even for modified engines. However, there are also some additional parts, listed below, which may need to be replaced. Fortunately, most of them are cheap, but all the more reason to replace them - it's too much work to risk repeating to replace a $10 part! At least be sure to inspect all parts listed below.

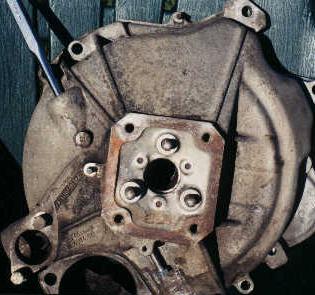

| The old cars sometimes get enough corrosion to REALLY hold the release lever shaft tight! I have heard of broken housings in the ensuing battle. There IS another way but you must get access to the top of the housing first. (Pull the engine?) Use a punch to drive the shaft out. Miss the stake which locates the shaft |

.

| Check the splines on the torque tube shaft, any damage can cause the clutch disc to hang up and make shifting tricky or impossible. | |

| Replace the pilot bearing in the flywheel; a badly worn pilot bearing can eat clutch discs | |

| Plan to replace the throwout bearing guide tube, part # 016 141 181. It's an inexpensive part, but is easily bent or corroded, and can cause the throwout bearing to hang up and prevent proper shifting. | |

| Clean (with brake cleaner) and inspect the flywheel surface for damage (scratching or grooves) or burning (blue spots). If so, have the flywheel turned at a machine shop. The clutch will grip so much better on a fresh surface. | |

| The torque tube is located into the back of the bellhousing with 4 bolts (easily accessed from below) and 3 pins. After the bolts are removed, it may take a bit of effort to slide the torque tube off the pins, if corrosion has set in. | |

| Check the condition of the torque tube bearings while the torque tube is pulled back by placing the trans in neutral and spinning the input shaft with your hand. The shaft should spin freely without any "grinding" sensation; if there is a grinding sensation like a worn bearing, then the 3 bearings in which the shaft is supported are probably bad and will need to be replaced. Instructions on how to do that are in the Transmission section. |